TAH CHUNG STEEL CORP was founded in Oct, 1968, Taiwan. Our company mainly engaged in manufacturing and trading of wire, special steel, bars, coils, welded steel wire mesh, brackets, and 3D light-weight wall panels. We supply a wide range of steel types, comprehensive sufficient material sources, and a full range of sizes, with specifications ranging from 0.2 to 100mm and a monthly production capacity of 15,000 tons. TAH CHUNG absolutely is the premier bar and wire supplier in the field.

Under stringent requirements on quality and working environment, our company has won the affirmation of ISO9001 international quality assurance certification.

In order to improve the competitiveness of our products, we will not only strengthen the improvement and development of our products, but also make efforts towards high quality and added value in order to meet the demands of the steel market and to bring more profit to our customers.

Our company also provides professional OEM & ODM service. If you have any further question, please feel free to contact us.

In-depth understanding of client needs, planning process control.

Thoroughly implement the operating guidelines and achieve

the quality objectives set by the Quality Management Committee.

The quality management system is designed for continuous improvement.

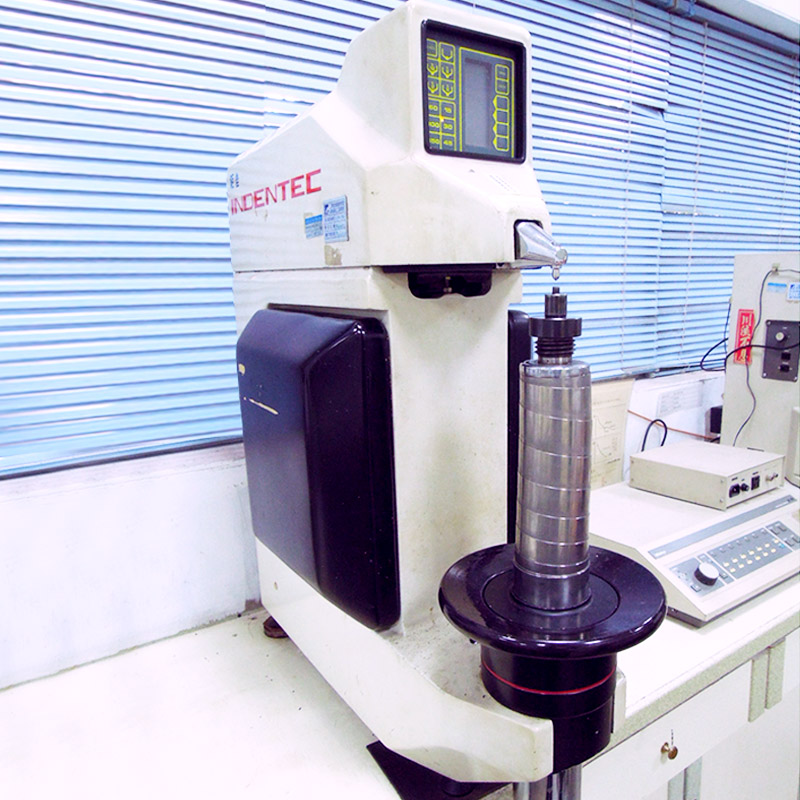

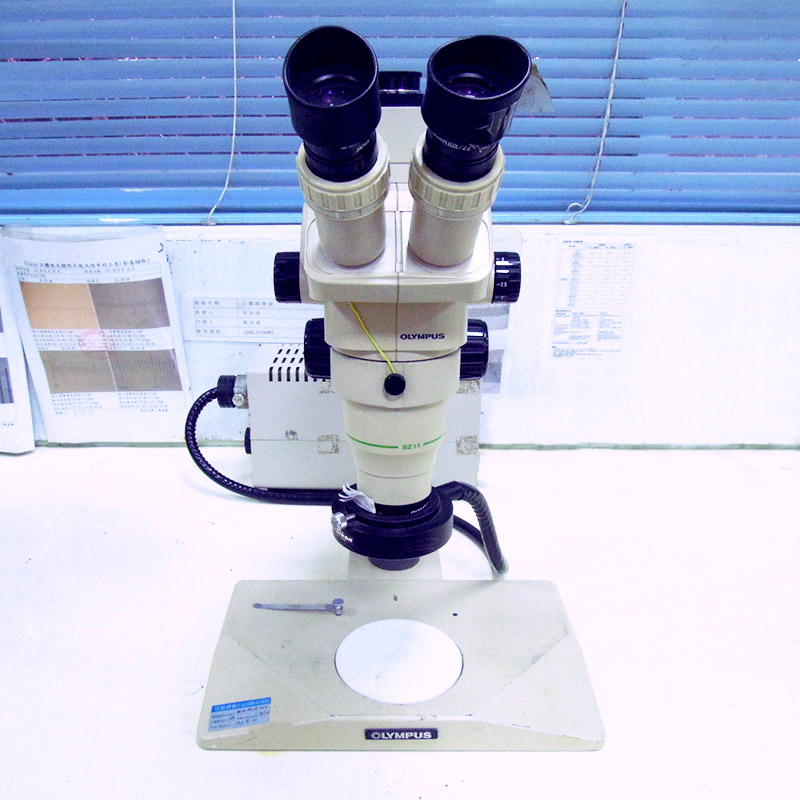

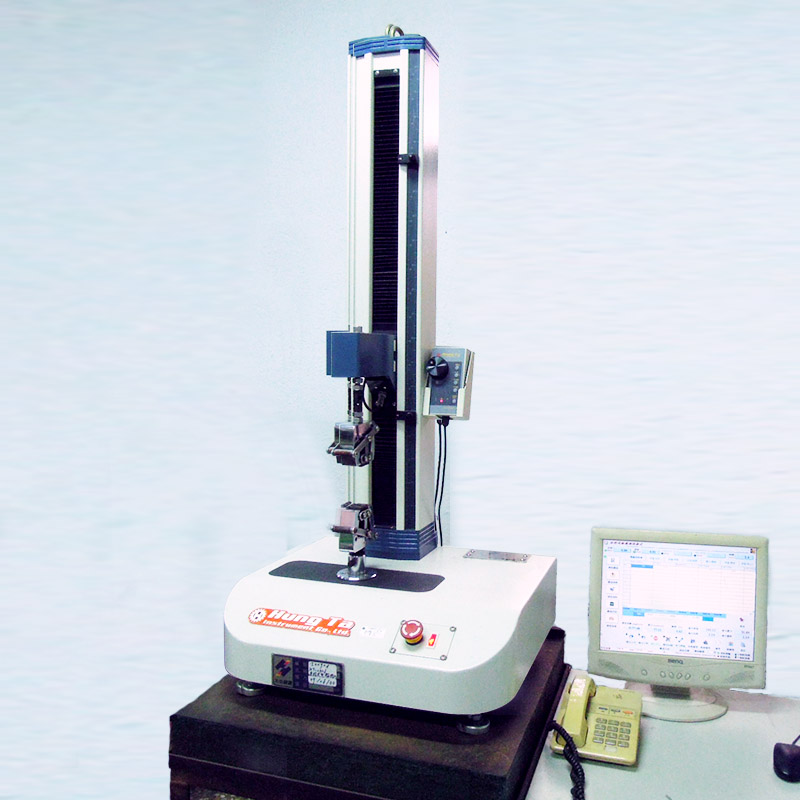

The material laboratory of our quality assurance

department is certified by the National

Accreditation Foundation (TAF), which ensures the accuracy,

traceability and quality of test results and brings them in

line with international standards.

1. Instead of doing go-it alone strategy nor price-cutting competition, we work on production-marketing coordination and market segmentation etc.

2. Combine upstream, midstream and downstream practitioner, under production techniques and research & development also carry on horizontal division of labor and vertical integration, we create coexistence and co-prosperity development model.

3. Moderate expansion of business scale and increase the added value of products.

1. Maintain friendly relations with foreign steel industry to exchange information and technology in order to create marketing channels

2. Selecting regions with growth potential as priority marketing targets.

3. To improve technology and develop high value-added products we meet the needs of downstream customers and assist them to reduce costs in order to enhance their international competitiveness.