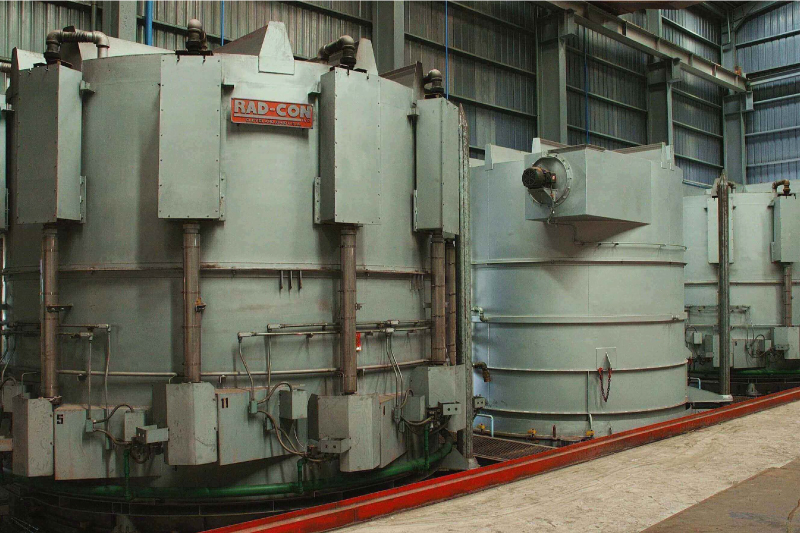

RAD-CON, Inc. is a leading supplier of bell-type batch annealing furnace (BAF) equipment that uses a protective atmosphere of 100% hydrogen. The annealing process softens metal which is a key operation within cold-rolling and finishing mills that produce coils of strip and wire. The 100% hydrogen protects the metal and makes the process more efficient.

In addition to the equipment, RAD-CON provides design,installation, and operational support of complete annealing facilities. The equipment is manufactured primarily at an affiliated company in Cleveland, Ohio USA. Some equipment is also manufactured in qualified partner shops located near its headquarters or for bulky items near the markets served. Equipment designs are complemented by the decades of experience in annealing various alloys to specific finish requirements, for both ferrous and non-ferrous alloys.

a. Model: SCWD-600(60HP)

b. Horsepower: Each 60 HP AC Motor plus Inverter

c. Drum Dia: 600mm

a. Model: NSC-600S (Counter Clockwise or Clockwise)

b. Ability: 4.0mm ~ 2.1mm

c. Drum Dia: 600mm

d. Speed: 0 ~ 200M/min (60HZ)

a. Model: IVD-800(100HP)

b. Dia. of supply wire (mm): Under 12mm

c. Drum Dia: 800mm

d. Each wire carrier afford: 0 ~ 2250kg.

e. Wire drawing speed: 0 ~65 M/min (60HZ)

f. Tensile strength: 100 kg/m㎡

a. Model:IVD-1000(100HP)

b. Dia. of supply wire (mm):Under 20mm

c. Drum Dia:1000mm

d. Wire drawing speed: 25 M/min(60HZ) Tensile strength: under 100 kg/mm2 Rate reduction: 19 %

a. Model: DCD-600/460(60HP /50HP)

b. Drum Dia: Up drum: 600mm Down drum: 460mm