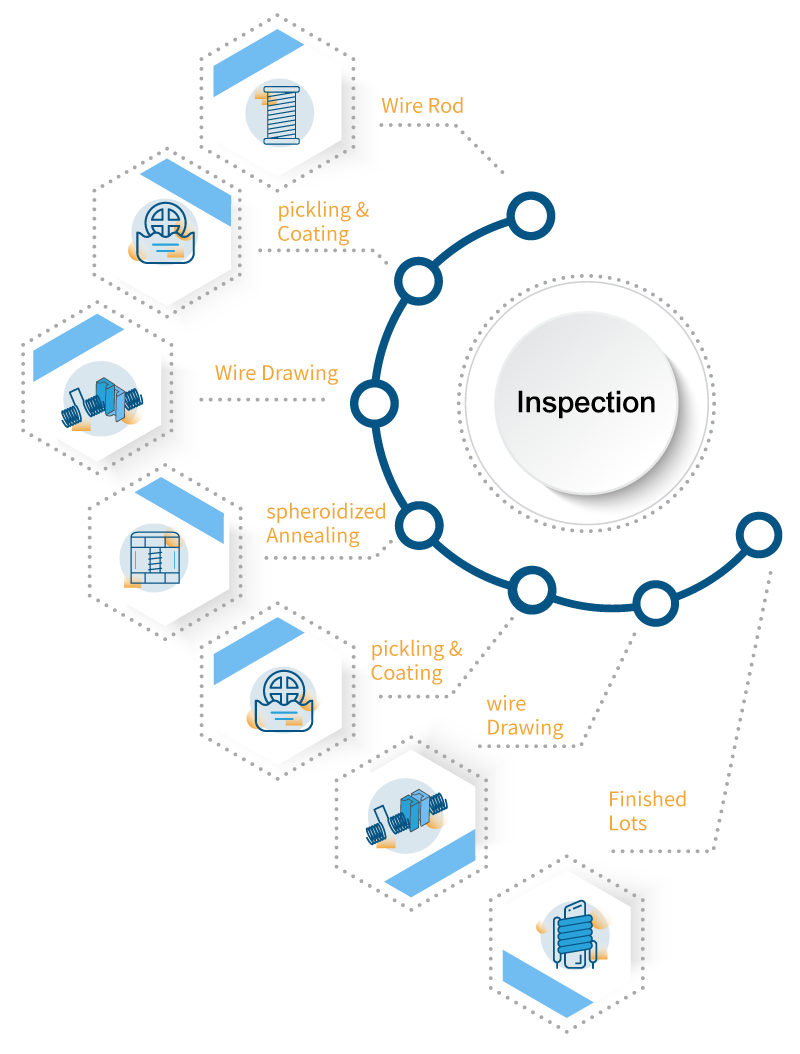

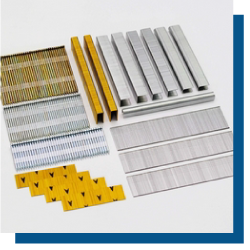

With a carbon content of 0.53-0.58 and a high SI of 1.30-1.60, spring steel is a special alloy steel used for the production of various types of springs and other elastic components. According to performance requirements and usage conditions, it can be divided into ordinary alloy spring steel and special alloy spring steel. Spring steels have an excellent combination of properties, excellent metallurgical quality (high purity and homogeneity), good surface quality, precise shape and dimensions for spring materials, such as motorcycle coil springs, suspension springs.

Common Materials: 9254, 60SICRV, SUP3-12, 9254C

If you have other requested specification, please contact with sales or highlight on the order.

Used in spring materials, such as coil springs for motorcycles, suspension springs.

|

Material Specification |

Click for more info |

Mechanical Chart |

Click for more info |