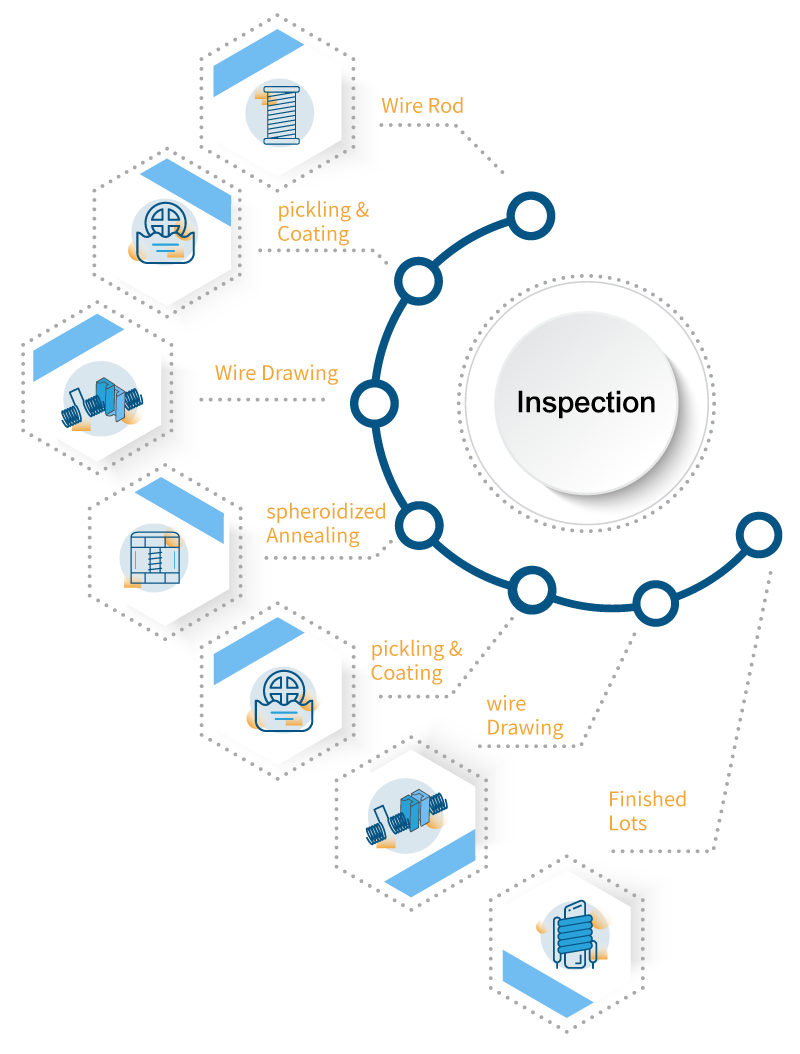

Carbon content between 0.01%~0.25% which called low carbon steel , low carbon steel is carbon steel with short tempering time, soft, stamping resistance and ductility, mainly used for producing hardware parts and special-shaped steel.

If you have other requirements, such as testing the surface hardness and core hardness or require the specified material, we can also customize the production according to your needs.

Low carbon content materials with soft characteristics are easy to process;

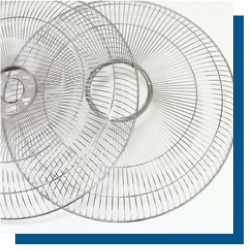

Applications: electric fan net, wire rack, lighting, barbecue rack, toy car shaft, CD rack, wine rack, basket, dish rack, fruit basket, bathroom rack with multifunctional kitchen basket series, fruit plate series, tableware series, bathroom series, barbecue series, wine rack series, cup holder series, indoor storage rack series, clothing rack series, shoe rack series, chopstick cage series, hook series, heat pad series, mask, chicken cage, dog cage, hoop arts and crafts processing, etc.

|

Material Specification |

Click for more info. |

Mechanical Chart |

Click for more info. |