Sign in

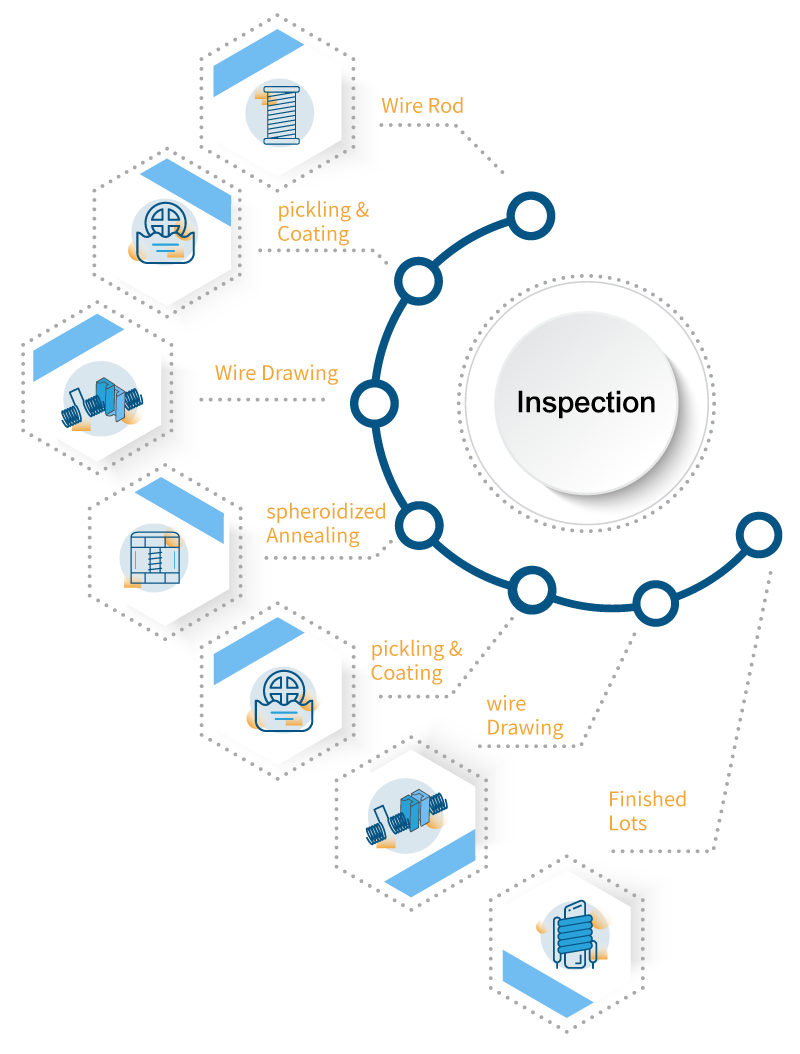

It is widely used for forgings with large deformation. It has better cold forgeability than general carbon steel 1006-1022, and is an excellent cold forging steel. If you have other requirements, such as testing surface hardness and core hardness and require specified materials, we can also customize and produce according to your needs. Main materials commonly used: CH6A, CH8A, CH10A, CH12A, CH18A, CH22A

If you have other requested specification, please contact with sales or highlight on the order.

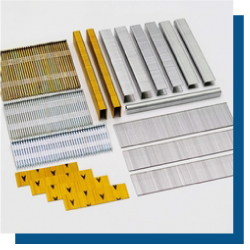

Mainly used for cold forging screws with the largest head, horn speakers.

|

Material Specification |

Click for more info |

Mechanical Chart |

Click for more info |